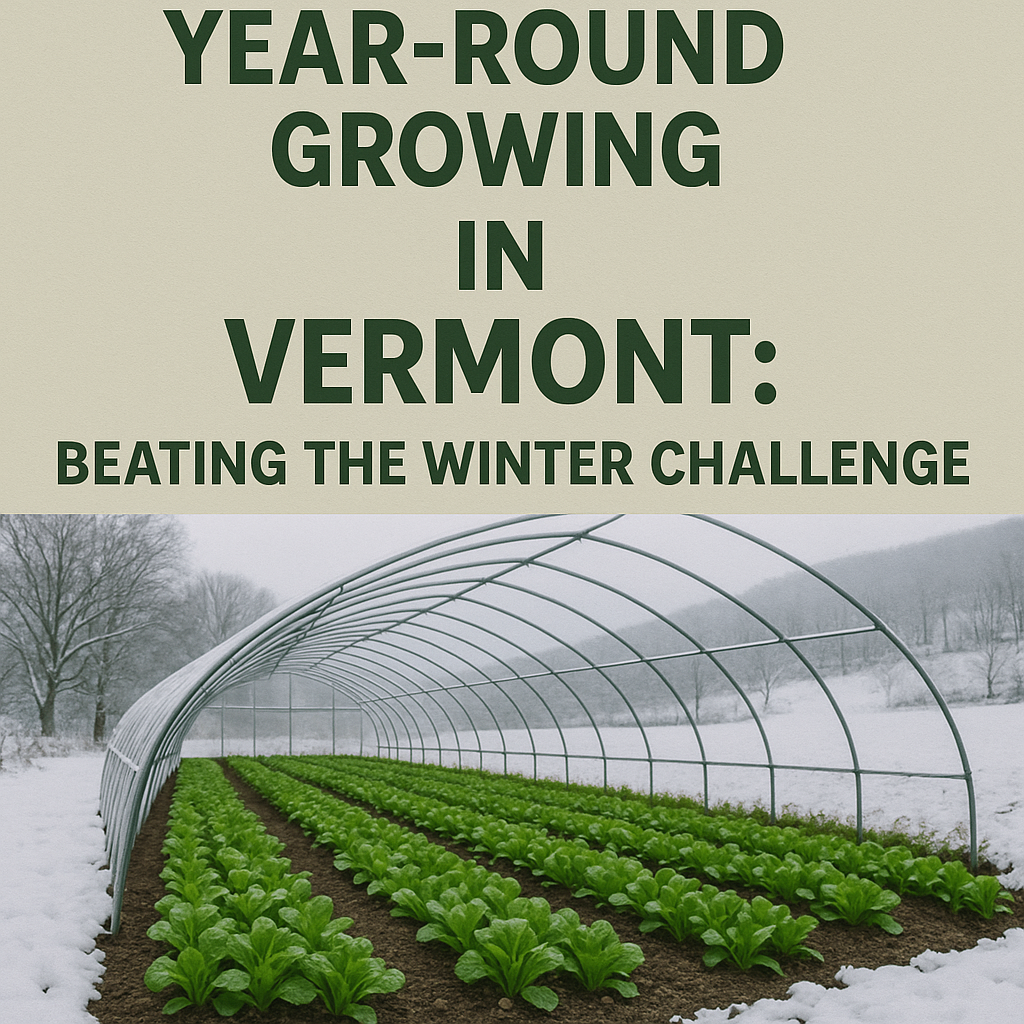

Featured Image: A snow-covered Vermont landscape with a glowing greenhouse in the foreground, warm light emanating from inside showing lush green plants growing within. Steam visible from ventilation systems, creating a dramatic contrast between the cold exterior and thriving interior growing environment.

Vermont’s harsh winters have traditionally defined the limits of local food production, with most farms shutting down operations from November through March. However, innovative growers across the Green Mountain State are rewriting the rules of seasonal agriculture, proving that fresh, local production can thrive even when temperatures drop below zero.

The challenge is real: Vermont winters bring temperatures as low as -30°F, minimal daylight hours, and heating costs that can make or break a growing operation. Yet the rewards for successful year-round production are substantial – premium pricing, dedicated customer bases, and the satisfaction of providing fresh food when it’s needed most.

Understanding Vermont’s Winter Growing Environment

Vermont’s climate presents unique challenges that must be understood before attempting year-round production:

Temperature Extremes: Average winter temperatures range from 10-30°F, with frequent dips below zero. Heating costs can represent 40-60% of winter operating expenses.

Limited Daylight: December and January provide only 8-9 hours of daylight, with weak solar radiation. Natural light levels drop to 5-10% of summer intensity.

Snow Load: Vermont building codes require structures to withstand 40+ lbs/sq ft of snow load. Greenhouses must be engineered accordingly.

Energy Costs: Vermont electricity rates average $0.16-0.20/kWh, making efficient heating and lighting systems essential.

The Opportunity

Despite these challenges, winter growing in Vermont offers unique advantages:

Premium Market Pricing: Fresh, locally-grown produce commands 40-60% higher prices in winter months.

Reduced Competition: Fewer local producers means less market saturation and stronger customer relationships.

Consistent Restaurant Demand: Vermont’s year-round tourism industry creates steady demand for local products.

Extended Growing Season Revenue: Year-round production can double or triple annual farm revenue compared to seasonal operations.

Infrastructure Solutions for Cold Climate Growing

Greenhouse Design Optimization

Double-Wall Construction: Polycarbonate or double-layer poly houses provide R-values of 1.5-2.0, significantly reducing heat loss compared to single-wall structures.

Thermal Mass Integration: Water barrels, concrete floors, or stone walls absorb heat during the day and release it at night, moderating temperature swings.

Ground-to-Air Heat Exchangers: Underground tubes leverage stable ground temperatures (45-50°F at 6-foot depth) to pre-warm incoming air.

Proper Orientation: South-facing structures with steep roof angles maximize winter solar gain while minimizing snow accumulation.

Advanced Heating Systems

Radiant Floor Heating: Circulating warm water through floor-embedded tubing provides efficient, even heat distribution while warming root zones.

Biomass Heating: Wood chip or pellet boilers can reduce heating costs by 40-60% compared to propane or oil systems.

Heat Recovery Ventilation: Capturing heat from exhaust air and transferring it to incoming fresh air improves energy efficiency by 60-80%.

Zone Heating: Dividing greenhouse space into zones allows for crop-specific temperature management and energy conservation.

Energy Conservation Strategies

Thermal Curtains: Automated curtain systems can reduce heat loss by 30-40% during nighttime hours.

Perimeter Insulation: Insulating foundation walls and the first 2-3 feet of greenhouse walls dramatically reduces heat loss.

Air Sealing: Eliminating air leaks through caulking, weatherstripping, and proper construction techniques can reduce heating loads by 20-30%.

Crop Selection for Winter Success

Not all crops are suited for Vermont winter production. Successful winter growers focus on varieties that tolerate low light and cool temperatures while maintaining market appeal.

Optimal Winter Crops

Leafy Greens:

- Spinach: Cold-tolerant varieties like ‘Winter Bloomsdale’ thrive in 40-50°F conditions

- Kale: Extremely cold-hardy, actually improves in flavor after frost exposure

- Asian Greens: Bok choy, mizuna, and tatsoi excel in cool conditions

- Lettuce: Butterhead and romaine varieties selected for cold tolerance

Herbs:

- Parsley: Biennial herbs that maintain quality through winter

- Cilantro: Cool-season crop that bolts less frequently in winter

- Chives: Perennial herbs that continue producing through winter

- Oregano and Thyme: Mediterranean herbs that tolerate cool, dry conditions

Microgreens:

- Pea shoots: Fast-growing and cold-tolerant

- Sunflower greens: High-value crop with quick turnaround

- Radish microgreens: Spicy flavor appreciated in winter cuisine

Variety Selection Criteria

Cold Tolerance: Choose varieties specifically bred for low-temperature performance.

Low-Light Performance: Select cultivars that maintain quality under reduced light conditions.

Disease Resistance: Winter’s high humidity conditions favor disease development; resistant varieties are essential.

Market Demand: Focus on crops with proven winter market demand and premium pricing potential.

Lighting Solutions for Vermont Winters

Supplemental lighting becomes essential for maintaining production quality and timing during Vermont’s dark winter months.

LED Technology Advantages

Energy Efficiency: Modern LED systems provide 40-50% energy savings compared to HPS lighting.

Heat Management: LEDs produce less heat, reducing cooling costs and allowing closer placement to plants.

Spectrum Control: Full-spectrum LEDs can be tuned for specific growth phases and crop requirements.

Longevity: 50,000+ hour lifespans reduce replacement costs and maintenance.

Lighting Strategies

Photoperiod Extension: Adding 4-6 hours of supplemental light extends the effective day length during short winter days.

Light Intensity Supplementation: Boosting light levels to 200-400 μmol/m²/s maintains summer-like growth rates.

Targeted Spectrum: Red and blue wavelengths optimized for photosynthesis while minimizing energy consumption.

Zone Lighting: Providing light only where needed reduces energy costs and allows crop-specific optimization.

Managing Winter Production Challenges

Humidity Control

Winter growing creates high humidity conditions that can lead to disease problems:

Ventilation Management: Balancing fresh air exchange with heat conservation requires sophisticated control systems.

Dehumidification: Mechanical dehumidifiers may be necessary during periods of high humidity and low temperatures.

Air Circulation: Continuous air movement prevents stagnant conditions that promote fungal diseases.

Pest and Disease Management

Enclosed winter environments can harbor pest and disease problems:

Preventive Sanitation: Regular cleaning and disinfection protocols prevent problem establishment.

Beneficial Insects: Predatory mites and other beneficials can be maintained in heated environments.

Environmental Controls: Maintaining optimal temperature and humidity reduces plant stress and disease susceptibility.

Water Management

Temperature Considerations: Cold water can shock plant roots; water heating may be necessary.

Humidity Balance: Overwatering in winter conditions leads to root rot and humidity problems.

System Winterization: Preventing freeze damage to irrigation systems during extreme cold periods.

Economic Strategies for Winter Production

Cost Management

Energy Budgeting: Heating costs should be factored at $2-5 per square foot per month during peak winter.

Crop Selection: Focus on high-value crops that justify increased production costs.

Efficiency Investments: Energy-efficient equipment pays for itself through reduced operating costs.

Market Development

Restaurant Partnerships: Develop relationships with restaurants that appreciate consistent, high-quality local ingredients year-round.

Winter CSA Programs: Offer winter shares focused on storage crops supplemented with fresh greenhouse production.

Specialty Markets: Target health-conscious consumers willing to pay premium prices for fresh, local produce in winter.

Value-Added Products: Consider processing excess production into preserved goods to maximize revenue.

Technology Integration for Winter Success

Environmental Monitoring

Sensor Networks: Monitor temperature, humidity, light levels, and soil conditions continuously.

Automated Controls: Computer-controlled systems manage heating, ventilation, and lighting based on real-time conditions.

Data Logging: Historical data helps optimize systems and predict maintenance needs.

Remote Monitoring: Smartphone alerts allow immediate response to system problems.

Energy Management Systems

Smart Thermostats: Programmable controls optimize heating schedules based on production requirements.

Load Management: Coordinating electrical loads prevents demand spikes and reduces utility costs.

Renewable Integration: Solar panels and wind systems can offset winter energy consumption.

Success Stories from Vermont Growers

Several Vermont operations have proven that year-round production is not only possible but profitable:

Green Mountain Greens (Waterbury): This 2,500 sq ft greenhouse operation focuses on microgreens and baby leafy greens, maintaining production through Vermont winters using efficient LED lighting and biomass heating.

Vermont Hydroponic Produce (Waitsfield): Specializing in lettuce and herbs, this operation uses thermal curtains and radiant heating to maintain consistent production while managing energy costs.

Four Season Farm (Harborside, ME – similar climate): Eliot Coleman’s pioneering work with unheated greenhouses and row covers demonstrates that cold-hardy crops can be grown with minimal energy inputs.

Planning Your Winter Growing Operation

Phase 1: Assessment and Planning

Site Evaluation: Assess solar exposure, wind protection, and utility access.

Market Research: Identify potential customers and price points for winter produce.

Financial Planning: Calculate startup costs, operating expenses, and revenue projections.

Phase 2: Infrastructure Development

Greenhouse Construction: Build or retrofit structures for winter production.

Heating System Installation: Install efficient heating systems sized for Vermont conditions.

Lighting Setup: Add supplemental lighting for consistent production.

Phase 3: Production Testing

Crop Trials: Test varieties and growing methods before full-scale production.

System Optimization: Fine-tune environmental controls and growing protocols.

Market Development: Build customer relationships and establish sales channels.

Common Mistakes to Avoid

Underestimating Energy Costs: Heating costs can quickly overwhelm revenues if not properly planned.

Inadequate Insulation: Poor insulation leads to excessive energy consumption and poor growing conditions.

Wrong Crop Selection: Growing heat-loving crops in winter conditions leads to poor quality and low yields.

Insufficient Lighting: Underestimating light requirements results in slow growth and poor plant quality.

Poor Ventilation: Inadequate air exchange creates disease-promoting conditions.

The Future of Winter Growing in Vermont

As technology improves and energy costs stabilize, year-round growing in Vermont will become increasingly viable. Advances in LED efficiency, heating technology, and automation are making winter production more accessible to small and medium-scale operations.

Emerging Technologies:

- Heat pump systems optimized for greenhouse applications

- Advanced thermal storage systems

- AI-controlled environmental management

- Improved crop varieties bred for low-light conditions

Policy Support: Vermont’s commitment to local food systems and renewable energy creates opportunities for grants and incentives supporting year-round agriculture.

Getting Started

For growers considering year-round production in Vermont:

Start Small: Begin with a modest setup to learn the systems and understand costs before scaling up.

Focus on Efficiency: Invest in energy-efficient systems from the beginning – they pay for themselves quickly.

Develop Markets First: Establish customer relationships before ramping up production.

Plan for Maintenance: Winter systems require more maintenance; budget time and resources accordingly.

Network with Other Growers: Join local growing groups and learn from experienced winter producers.

Year-round growing in Vermont requires careful planning, significant investment, and attention to detail. However, for growers willing to embrace the challenge, it offers the opportunity to serve customers with fresh, local produce throughout the year while building a more resilient and profitable agricultural business.

The key to success lies in understanding Vermont’s unique climate challenges and designing systems that work with, rather than against, the natural environment. With proper planning and execution, Vermont’s harsh winters can become a competitive advantage rather than a limitation.