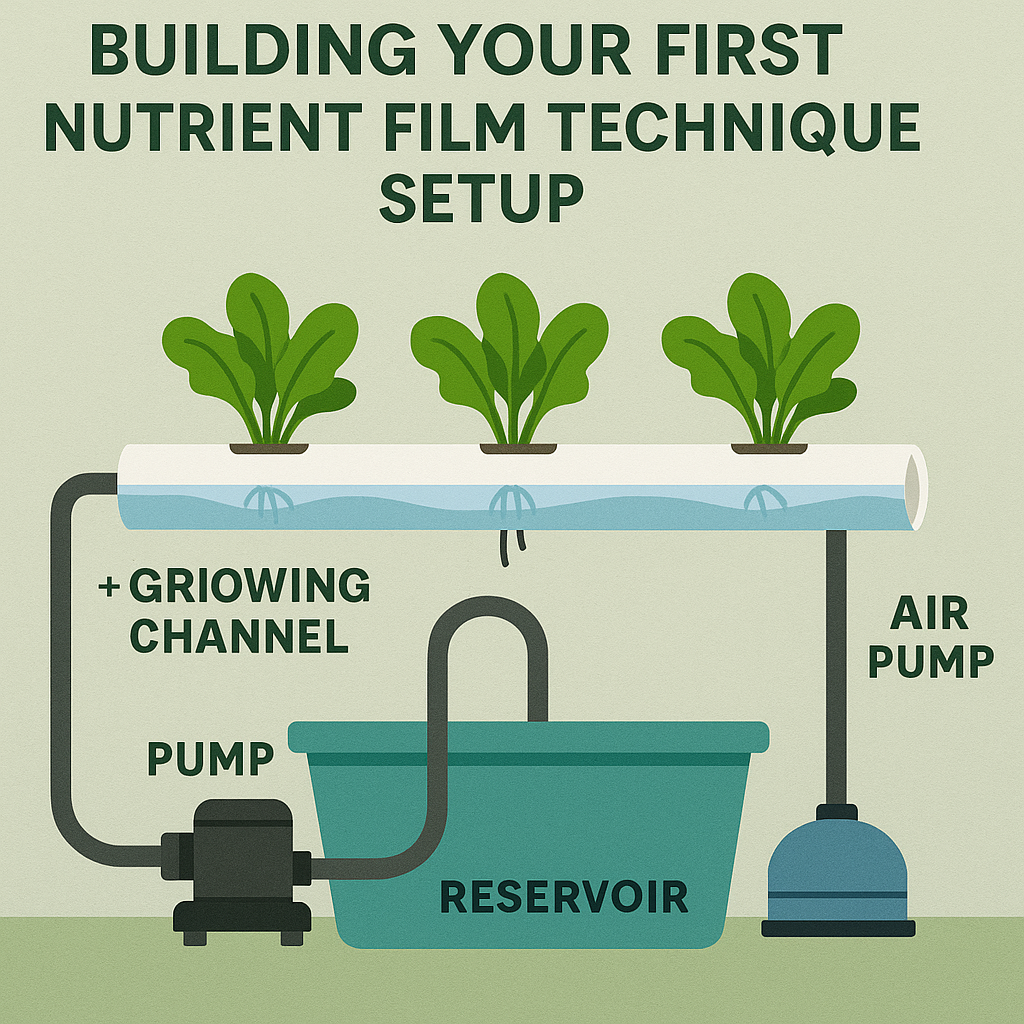

Featured Image: A clean, professional NFT hydroponic system showing white PVC channels with healthy lettuce and herb plants growing in neat rows. Include a visible nutrient reservoir, pump system, and return drainage system. The setup should appear in a greenhouse environment with good lighting.

Nutrient Film Technique (NFT) represents one of the most elegant solutions in hydroponic growing – a continuous flow system that delivers precisely the right amount of water and nutrients while maintaining optimal oxygen levels at the root zone. For growers seeking efficient, scalable, and productive hydroponic systems, NFT offers compelling advantages combined with relatively simple construction and maintenance requirements.

Developed in the 1960s by Dr. Allan Cooper at the Glasshouse Crops Research Institute in England, NFT has become a cornerstone of commercial hydroponic production worldwide. Its success lies in the perfect balance of nutrient delivery, oxygenation, and resource efficiency.

How NFT Systems Work

The fundamental principle of NFT is elegantly simple: a thin film of nutrient solution continuously flows through slightly sloped channels, providing plant roots with constant access to water, nutrients, and oxygen. Unlike deep water culture systems where roots are submerged, or drip systems with intermittent feeding, NFT provides continuous, gentle delivery of everything plants need.

The NFT Process:

1. Nutrient Delivery: A pump draws nutrient solution from a reservoir and delivers it to the higher end of growing channels.

2. Film Flow: The solution flows as a thin film (2-3mm deep) along the bottom of sloped channels, contacting plant roots.

3. Root Interaction: Plant roots absorb nutrients and water while maintaining access to oxygen in the air space above the film.

4. Solution Return: Used nutrient solution flows to the lower end of channels and returns to the reservoir for recirculation.

5. Continuous Cycle: The process repeats continuously, providing plants with consistent nutrition and hydration.

Advantages of NFT Systems

Water Efficiency: NFT systems use 80-90% less water than traditional soil growing by recycling nutrient solution continuously.

Nutrient Control: Precise control over nutrient concentration and pH allows for optimal plant nutrition throughout growth cycles.

Oxygenation: The thin film design ensures roots receive excellent oxygen levels, promoting healthy growth and preventing root rot.

Space Efficiency: Vertical growing capability and compact design maximize production per square foot.

Clean Growing: Soilless system eliminates soil-borne pests and diseases while producing clean, easy-to-harvest crops.

Scalability: Systems can be easily expanded by adding more channels or levels.

Resource Efficiency: Recirculating design minimizes nutrient waste and reduces fertilizer costs.

System Components and Design

Growing Channels

Channel Material: Food-grade PVC, ABS plastic, or purpose-built NFT channels. Standard sizes range from 4-6 inches wide.

Channel Design: Rectangular or round channels with removable lids containing net pot holes spaced 4-8 inches apart depending on crop requirements.

Slope Requirements: Channels must slope 1:30 to 1:40 (approximately 1.5-2.5 degrees) to ensure proper flow without excessive speed.

Length Considerations: Maximum recommended length is 30-40 feet to prevent nutrient depletion and pH drift along the channel.

Reservoir System

Size Calculation: Reservoir capacity should equal 1-2 gallons per growing site to provide adequate buffer and system stability.

Material Selection: Food-grade plastic or fiberglass reservoirs with opaque walls to prevent algae growth.

Location: Position below growing channels to enable gravity return of nutrient solution.

Aeration: Air stones or venturi systems maintain dissolved oxygen levels in the reservoir.

Pump and Circulation

Pump Selection: Submersible or inline pumps sized to deliver 1 gallon per minute per 4-inch channel.

Flow Rate: Optimal flow creates a 2-3mm deep film – too little causes dry spots, too much drowns roots.

Distribution Manifold: PVC pipe system distributes nutrient solution evenly to all channels.

Return System: Gravity-fed collection channels return solution to reservoir with minimal pump requirement.

Support Structure

Frame Construction: Sturdy framework supporting channels at proper slope with allowance for plant weight.

Level Adjustment: Adjustable legs or shims enable precise slope calibration.

Material Options: PVC pipe, aluminum extrusion, or steel construction depending on scale and permanence.

Building Your First NFT System

Planning and Design

Space Assessment: Measure available growing space and determine channel layout for maximum efficiency.

Crop Selection: Choose appropriate crops for your first system – leafy greens and herbs are ideal for beginners.

Scale Decision: Start with 4-6 channels to learn the system before expanding to commercial scale.

Component Sourcing: Create detailed parts list including channels, fittings, pump, reservoir, and monitoring equipment.

Construction Process

Step 1: Frame Assembly

- Build support frame with proper slope (1:30 to 1:40)

- Ensure structural stability for plant and water weight

- Install adjustable legs for fine-tuning slope

- Test frame level and stability before proceeding

Step 2: Channel Installation

- Mount channels on frame with consistent spacing

- Verify proper slope using a level and measuring tape

- Install end caps and drainage fittings

- Cut holes for net pots according to crop spacing requirements

Step 3: Plumbing System

- Install reservoir below channel level

- Connect pump to distribution manifold

- Install individual feed lines to each channel

- Create return collection system to reservoir

- Test all connections for leaks

Step 4: Control Systems

- Install timer for pump cycling (typically continuous operation)

- Add EC and pH monitoring equipment

- Install temperature monitoring for solution and air

- Set up aeration system for reservoir

System Testing

Flow Testing: Run system with plain water to verify proper flow rates and distribution.

Leak Detection: Check all connections and joints for leaks before adding nutrients.

Level Verification: Confirm channels maintain proper slope and film thickness.

Control Calibration: Calibrate pH and EC meters using standard solutions.

Nutrient Management in NFT

Solution Preparation

Base Nutrients: Use complete hydroponic fertilizers designed for recirculating systems.

Concentration Levels: Maintain EC between 1.8-2.4 mS/cm for most leafy greens and herbs.

pH Management: Keep pH between 5.5-6.5 for optimal nutrient uptake.

Water Quality: Start with low-EC water (under 0.4 mS/cm) for consistent results.

Monitoring and Adjustment

Daily Checks: Monitor EC, pH, and solution level daily during active growing periods.

Weekly Analysis: Conduct more detailed testing of individual nutrients if problems arise.

Solution Replacement: Replace entire solution every 2-3 weeks or when EC drops significantly.

Record Keeping: Maintain logs of all adjustments and plant responses for system optimization.

Crop Selection and Management

Ideal NFT Crops

Leafy Greens:

- Lettuce varieties (butterhead, romaine, leaf lettuce)

- Spinach and baby spinach

- Kale and Asian greens

- Swiss chard and beet greens

Herbs:

- Basil (all varieties)

- Cilantro and parsley

- Oregano and thyme

- Mint and lemon balm

Specialty Crops:

- Microgreens for quick turnaround

- Baby vegetables for premium markets

- Edible flowers in controlled environments

Planting and Spacing

Propagation: Start plants in rockwool cubes or similar inert media.

Transplant Timing: Move to NFT system when roots are 1-2 inches long.

Spacing Guidelines:

- Lettuce: 6-8 inches apart

- Herbs: 4-6 inches apart

- Leafy greens: 4-8 inches depending on mature size

Common Problems and Solutions

Flow-Related Issues

Uneven Flow:

- Cause: Improper channel slope or distribution

- Solution: Readjust channel level and check manifold design

Flow Blockages:

- Cause: Root growth blocking channels or debris accumulation

- Solution: Regular channel cleaning and root management

Insufficient Flow:

- Cause: Undersized pump or system leaks

- Solution: Upgrade pump capacity or repair leaks

Plant Health Issues

Nutrient Deficiencies:

- Cause: Incorrect EC levels or pH imbalance

- Solution: Adjust nutrient concentration and pH

Root Problems:

- Cause: Poor oxygenation or excessive moisture

- Solution: Improve aeration and check flow rates

Slow Growth:

- Cause: Inadequate lighting or temperature issues

- Solution: Optimize environmental conditions

System Maintenance

Regular Cleaning: Clean channels and reservoir between crops to prevent disease buildup.

Pump Maintenance: Check pump performance and clean intake screens regularly.

Monitor Replacement: Calibrate and replace pH/EC probes according to manufacturer schedules.

Scaling Up Your NFT Operation

Commercial Considerations

Production Planning: Calculate channel requirements based on harvest schedules and market demand.

Automation Options: Consider automated pH adjustment, nutrient dosing, and environmental controls.

Quality Control: Implement standardized procedures for consistency and food safety.

Economic Analysis: Track production costs, yields, and profitability per channel.

Advanced Features

Multi-Zone Systems: Separate channels for different crops or growth stages.

Vertical Growing: Stack channels to maximize production per square foot.

Climate Integration: Connect NFT controls with greenhouse environmental systems.

Data Logging: Monitor and record system performance for optimization.

Economic Benefits of NFT

Initial Investment: Moderate startup costs compared to other hydroponic systems.

Operating Efficiency: Low water and nutrient consumption reduce ongoing costs.

Labor Savings: Clean growing conditions and easy harvesting reduce labor requirements.

Yield Advantages: Higher yields per square foot than soil growing in most applications.

Year-Round Production: Continuous harvesting capability maximizes facility utilization.

Getting Started with NFT

For growers new to NFT systems:

Start Small: Build a 4-6 channel system to learn before investing in larger installations.

Choose Simple Crops: Begin with lettuce or herbs rather than complex fruiting crops.

Focus on Fundamentals: Master flow rates, nutrient management, and pH control before adding complexity.

Keep Records: Document everything to identify patterns and optimize performance.

Connect with Community: Join hydroponic growing groups for advice and troubleshooting support.

NFT systems offer an excellent entry point into commercial hydroponic production, combining simplicity with scalability. While the initial learning curve requires attention to detail, mastering NFT opens doors to efficient, profitable growing operations that can supply fresh, high-quality produce year-round.

The key to NFT success lies in understanding the relationship between flow, nutrition, and plant biology. When properly designed and managed, NFT systems provide the foundation for sustainable, productive hydroponic operations that can compete with any growing method for efficiency and quality.