Featured Image: A split-screen comparison showing a traditional garden plot with basic tools (watering can, soil thermometer, simple pH test strips) on one side, and a high-tech growing setup with digital sensors, smartphone monitoring, and automated systems on the other. Plants should be thriving in both setups to show this isn’t about technology replacement but enhancement.

The agricultural world stands at a fascinating crossroads where traditional farming wisdom meets cutting-edge sensor technology. While experienced growers have successfully cultivated crops for thousands of years using observation, intuition, and hard-earned knowledge, modern smart sensors promise to quantify and optimize what was once purely experiential. The question isn’t whether technology should replace traditional methods, but rather how the marriage of both approaches can create superior growing outcomes.

This comprehensive analysis examines the measurable differences between traditional growing methods and sensor-enhanced cultivation, providing data-driven insights into when each approach excels and how they can work together to achieve optimal results.

The Traditional Growing Approach

Traditional growing relies on human senses, experience, and established agricultural practices developed over generations. Skilled growers assess plant health through visual inspection, soil moisture by feel, and timing by seasonal patterns and plant behavior.

Strengths of Traditional Methods

Holistic Plant Assessment: Experienced growers observe subtle changes in plant color, leaf position, growth rate, and overall vigor that sensors cannot yet quantify.

Intuitive Problem Solving: Years of experience enable pattern recognition that identifies problems before they become measurable by instruments.

Cost Effectiveness: No equipment investment, maintenance, or calibration requirements reduce operational overhead.

Adaptability: Human judgment can adapt to unique situations and make decisions based on incomplete information.

Integrated Decision Making: Traditional growers consider multiple factors simultaneously – weather patterns, seasonal changes, market timing, and resource availability.

Limitations of Traditional Approaches

Subjectivity: Individual interpretation varies, leading to inconsistent results between different growers or even the same grower on different days.

Limited Precision: Human senses can only detect changes within certain thresholds, missing subtle but important variations.

Experience Dependency: New growers lack the accumulated knowledge needed for optimal decision-making.

Time Intensive: Manual monitoring requires significant time investment for large operations.

Reactive Management: Problems are often addressed after symptoms become visible rather than being prevented.

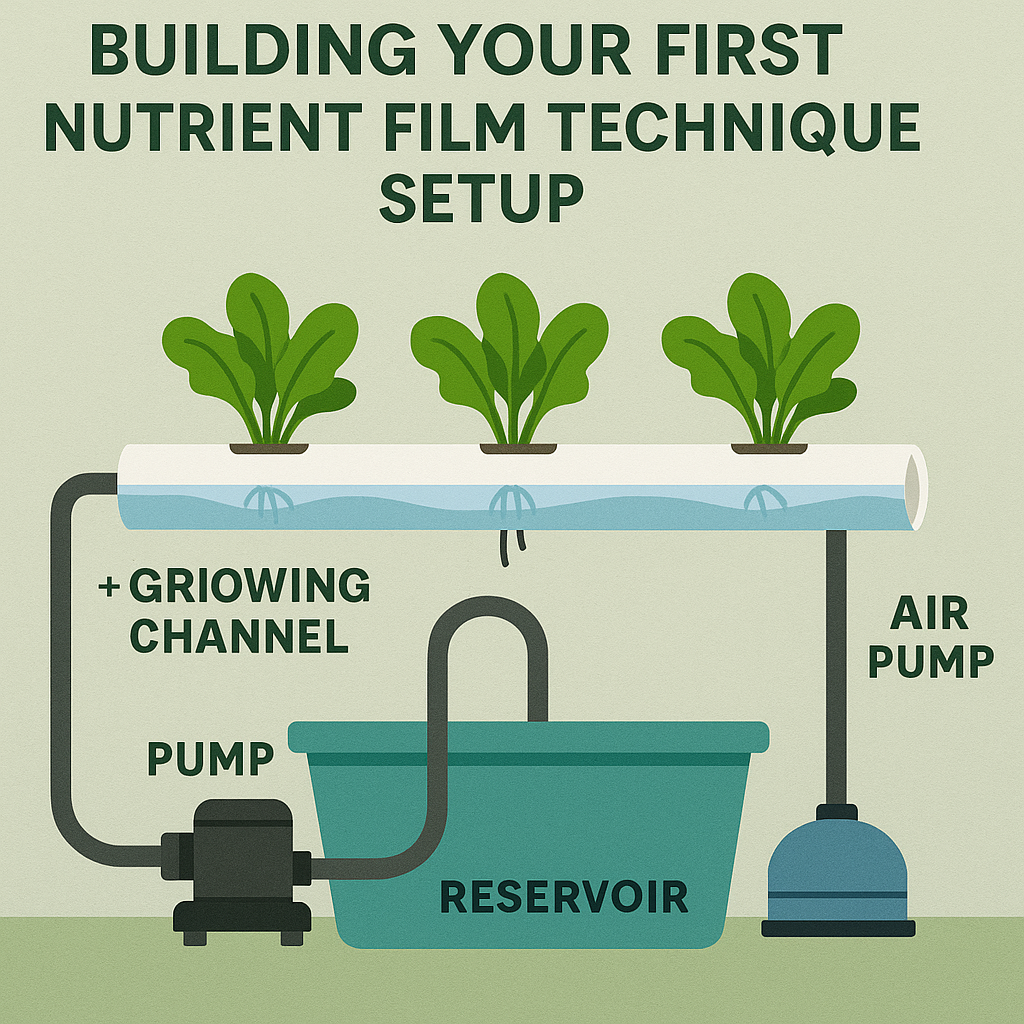

The Smart Sensor Revolution

Smart sensors provide continuous, quantified monitoring of growing conditions, enabling data-driven decision making and automated responses to changing conditions.

Key Sensor Technologies

Soil Moisture Sensors: Measure volumetric water content with ±2% accuracy, enabling precise irrigation timing.

Temperature and Humidity Sensors: Monitor air and soil temperature with 0.1°C precision and relative humidity within 2% accuracy.

Light Sensors: Measure photosynthetically active radiation (PAR) in μmol/m²/s for optimal lighting decisions.

pH and EC Sensors: Continuously monitor soil or solution chemistry with laboratory-grade precision.

CO2 Sensors: Track atmospheric carbon dioxide levels for photosynthesis optimization.

Plant-Based Sensors: Monitor stem diameter, leaf thickness, and sap flow for direct plant stress measurement.

Advantages of Sensor-Based Growing

Objective Data: Quantified measurements eliminate guesswork and provide consistent, repeatable results.

Continuous Monitoring: 24/7 data collection captures changes that might be missed during periodic manual checks.

Early Problem Detection: Sensors detect problems before visual symptoms appear, enabling preventive action.

Optimization Capability: Data analysis reveals optimal growing conditions for specific crops and varieties.

Automated Response: Systems can automatically adjust irrigation, heating, cooling, and lighting based on sensor inputs.

Scalability: Sensor networks can monitor large areas with minimal human intervention.

Data Historical Analysis: Long-term data collection enables trend analysis and predictive modeling.

Comparative Performance Analysis

Water Management Comparison

Traditional Method Results:

- Water usage: 100% baseline

- Irrigation frequency: Daily or as needed based on visual/tactile assessment

- Plant stress incidents: 15-25% of growing cycle

- Water waste: 20-40% due to over-watering

Sensor-Enhanced Results:

- Water usage: 25-40% reduction through precision timing

- Irrigation frequency: Optimized based on actual plant needs

- Plant stress incidents: 5-10% reduction

- Water waste: 60-80% reduction

Key Finding: Soil moisture sensors consistently reduce water usage by 25-40% while maintaining or improving plant health by eliminating both under and over-watering conditions.

Nutrient Management Efficiency

Traditional Approach:

- Fertilizer application: Schedule-based or symptom-reactive

- Nutrient deficiency detection: 7-14 days after onset

- Fertilizer waste: 30-50% due to imprecise timing

- Plant recovery time: 10-21 days after treatment

Sensor-Monitored Approach:

- Fertilizer application: Need-based with precise timing

- Nutrient deficiency detection: 2-5 days earlier than visual symptoms

- Fertilizer waste: 40-60% reduction through precision application

- Plant recovery time: 5-10 days due to early intervention

Environmental Control Precision

Traditional Environmental Management:

- Temperature control: ±5-8°F variation from optimal

- Humidity management: ±15-20% RH variation

- Light management: Seasonal dependence with limited supplementation

- Response time: 30-60 minutes to environmental changes

Sensor-Controlled Environment:

- Temperature control: ±1-2°F precision

- Humidity management: ±5% RH precision

- Light management: Optimal PAR levels maintained continuously

- Response time: 5-15 minutes automated response

Yield and Quality Comparisons

Productivity Metrics:

Leafy Greens Production Study (12-month comparison):

Traditional Growing:

- Average yield: 2.3 lbs/sq ft/month

- Crop loss rate: 12-18%

- Quality consistency: 75-80%

- Time to harvest: 35-45 days

Sensor-Enhanced Growing:

- Average yield: 3.1 lbs/sq ft/month (35% increase)

- Crop loss rate: 6-9% (50% reduction)

- Quality consistency: 90-95%

- Time to harvest: 28-35 days (20% faster)

Economic Impact Analysis

Initial Investment Comparison

Traditional Setup Costs (1,000 sq ft greenhouse):

- Basic tools and equipment: $500-800

- Manual irrigation system: $300-500

- Basic monitoring tools: $100-200

- Total initial investment: $900-1,500

Smart Sensor Setup Costs:

- Sensor network (10-15 nodes): $2,500-4,000

- Automated irrigation system: $1,500-2,500

- Environmental controls: $2,000-3,500

- Software and monitoring: $500-1,000

- Total initial investment: $6,500-11,000

Operating Cost Analysis

Annual Operating Costs (Traditional):

- Water and utilities: $2,400/year

- Fertilizers and amendments: $800/year

- Labor (monitoring and adjustments): $3,600/year

- Crop losses: $1,200/year

- Total annual costs: $8,000

Annual Operating Costs (Sensor-Enhanced):

- Water and utilities: $1,440/year (40% reduction)

- Fertilizers and amendments: $480/year (40% reduction)

- Labor (reduced monitoring): $1,800/year (50% reduction)

- Crop losses: $600/year (50% reduction)

- Sensor maintenance: $300/year

- Total annual costs: $4,620

Return on Investment Calculation

Annual Savings: $8,000 – $4,620 = $3,380

Additional Investment: $6,500-11,000 – $900-1,500 = $5,600-9,500

Payback Period: 1.7-2.8 years

5-Year ROI: 178-302%

Crop-Specific Performance Differences

Microgreens Production

Traditional Method:

- Germination rate: 80-85%

- Days to harvest: 8-12 days

- Yield per tray: 6-8 oz

- Quality grade: Good to Very Good

Sensor-Optimized Method:

- Germination rate: 92-96%

- Days to harvest: 7-10 days

- Yield per tray: 8-12 oz

- Quality grade: Excellent

Herb Production

Traditional Growing:

- Essential oil content: Baseline 100%

- Harvest frequency: Every 3-4 weeks

- Plant longevity: 3-4 months

- Disease incidence: 15-20%

Sensor-Enhanced Growing:

- Essential oil content: 15-25% higher

- Harvest frequency: Every 2-3 weeks

- Plant longevity: 4-6 months

- Disease incidence: 5-8%

Integration Strategies: Best of Both Worlds

The Hybrid Approach

The most successful modern growing operations combine traditional expertise with sensor technology, using each approach where it excels most:

Sensors Excel At:

- Continuous environmental monitoring

- Precise resource management

- Early problem detection

- Data logging and analysis

- Automated routine adjustments

Traditional Skills Excel At:

- Overall plant health assessment

- Complex problem diagnosis

- Seasonal planning and strategy

- Quality evaluation

- Creative problem-solving

Implementation Strategy

Phase 1: Foundation Sensors

- Install basic soil moisture and temperature sensors

- Implement automated irrigation based on soil moisture

- Maintain traditional monitoring for plant health assessment

- Cost: $1,000-2,000 for small operations

Phase 2: Environmental Control

- Add humidity, light, and air temperature sensors

- Implement climate control automation

- Continue visual monitoring for quality control

- Cost: Additional $2,000-3,500

Phase 3: Advanced Analytics

- Integrate plant-based sensors for direct stress monitoring

- Implement predictive analytics and machine learning

- Use traditional expertise to interpret and act on data insights

- Cost: Additional $3,000-5,000

Practical Implementation Guidelines

For Small-Scale Growers

Start Simple: Begin with soil moisture sensors and basic environmental monitoring.

Focus on High-Impact Areas: Prioritize sensors that address your biggest challenges (usually water management).

Maintain Manual Backup: Keep traditional tools and skills as backup systems.

Budget Gradually: Spread sensor investment over 2-3 years to manage cash flow.

For Commercial Operations

Comprehensive Planning: Design integrated sensor networks from the beginning.

Staff Training: Train employees to use both traditional skills and sensor data.

Data Management: Invest in software systems to analyze and act on sensor data.

Redundancy: Maintain backup systems for critical monitoring functions.

Common Implementation Challenges

Technical Challenges

Sensor Calibration: Requires regular maintenance and calibration for accurate readings.

Connectivity Issues: Wireless sensors can have communication problems in large facilities.

Data Overload: Too much data can be overwhelming without proper analysis tools.

Integration Complexity: Connecting different sensor systems can be technically challenging.

Human Factors

Learning Curve: Staff need training to interpret and act on sensor data effectively.

Over-Reliance Risk: Complete dependence on sensors can lead to problems when systems fail.

Cost Justification: Initial investment can be difficult to justify without clear ROI analysis.

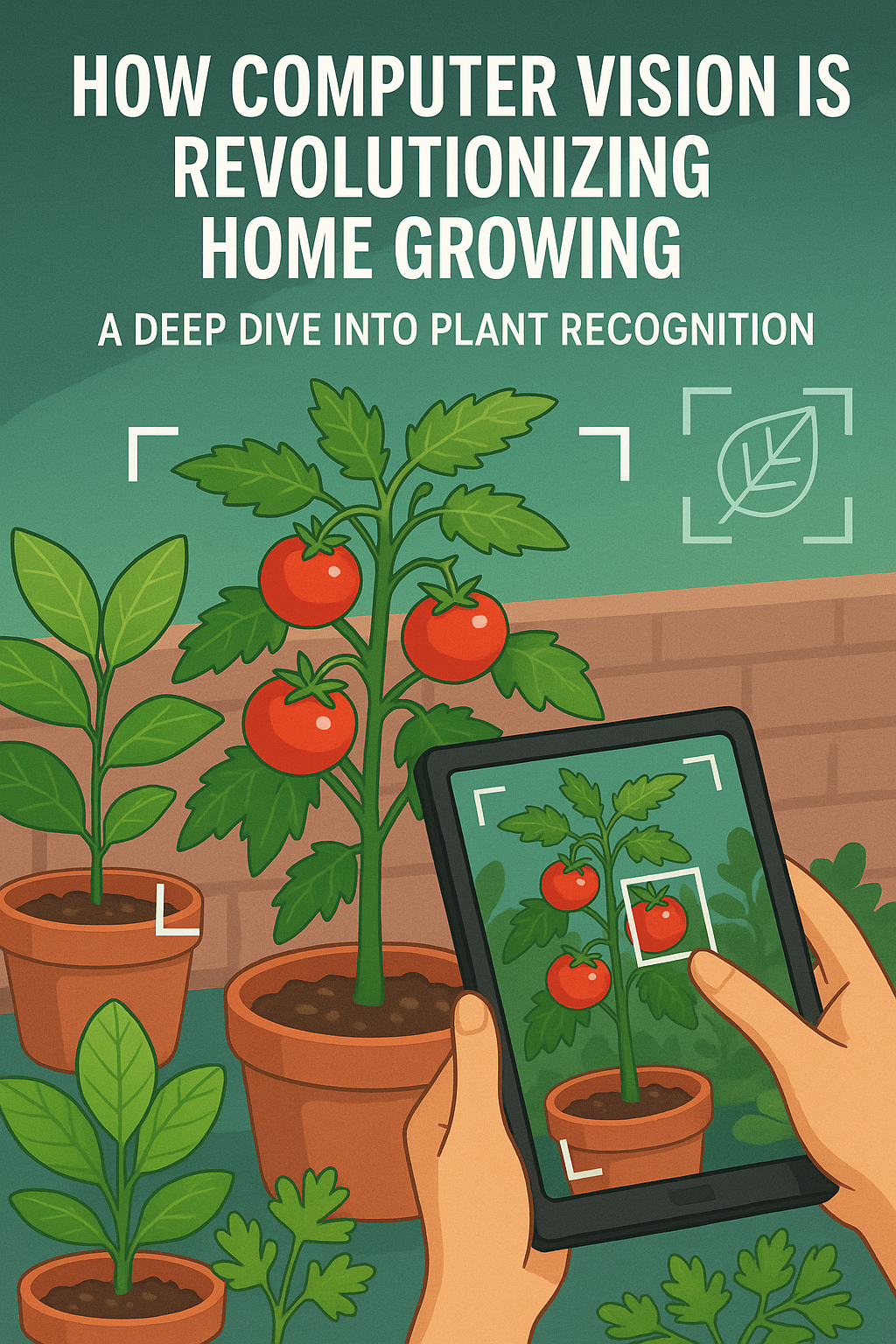

The Future of Growing: AI and Predictive Analytics

The next evolution combines sensor data with artificial intelligence to predict plant needs and optimize growing conditions proactively:

Predictive Modeling: AI analyzes historical sensor data to predict optimal harvest timing, disease outbreaks, and resource needs.

Automated Decision Making: Systems make complex decisions about nutrition, irrigation, and environmental control without human intervention.

Continuous Learning: AI systems improve over time, learning from each growing cycle to optimize future performance.

Integration with Market Data: Predictive systems consider market conditions and pricing to optimize production timing.

Making the Decision: When to Adopt Sensor Technology

Adopt Sensors When:

- Managing more than 500 sq ft of growing space

- Resource costs (water, energy, nutrients) are significant

- Crop losses exceed 10% regularly

- Labor costs for monitoring are substantial

- Consistency and quality are critical for market success

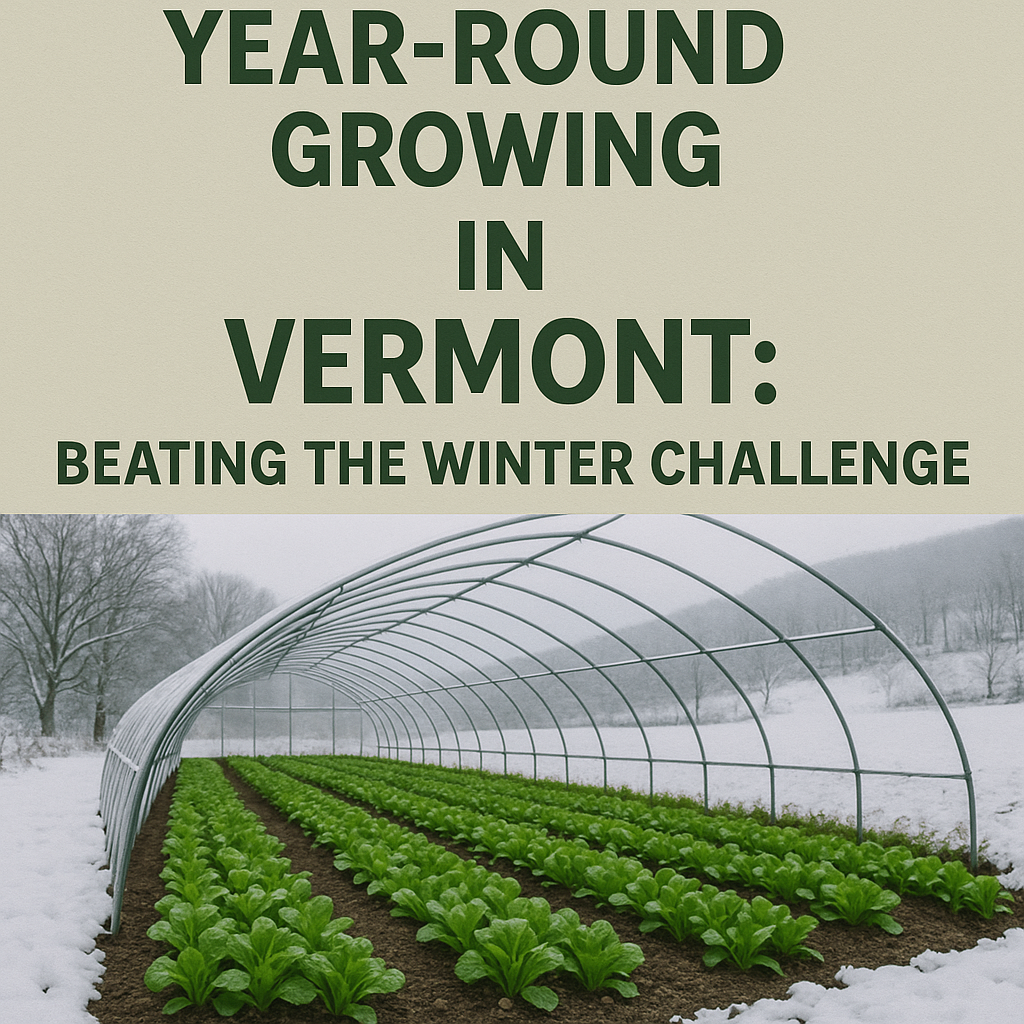

Stick with Traditional Methods When:

- Growing diverse, small-scale operations

- Initial investment capital is extremely limited

- Technical support and maintenance aren’t readily available

- Local markets don’t reward consistency with premium pricing

Success Metrics and Monitoring

To measure the success of sensor integration:

Production Metrics:

- Yield per square foot per month

- Crop loss percentage

- Time to harvest

- Quality consistency scores

Resource Efficiency:

- Water usage per pound of production

- Energy consumption per harvest cycle

- Fertilizer cost per pound of yield

- Labor hours per production unit

Financial Performance:

- Revenue per square foot

- Operating cost reduction

- Return on sensor investment

- Market premium capture

Conclusion: The Path Forward

The comparison between smart sensors and traditional growing methods reveals not a competition, but an evolution. Sensor technology doesn’t replace the need for agricultural knowledge and experience – it amplifies and quantifies it.

Key Findings:

- Sensor-enhanced growing delivers 25-40% resource savings

- Yields increase by 20-35% with sensor optimization

- Quality consistency improves by 15-20%

- ROI is achieved within 2-3 years for most operations

- The hybrid approach combining both methods produces optimal results

The most successful growers of the future will be those who master both traditional agricultural wisdom and modern sensor technology, using each approach where it provides the greatest advantage. Traditional skills provide the foundation and context, while sensors provide the precision and optimization needed for modern competitive agriculture.

As sensor costs continue to decrease and capabilities increase, the question isn’t whether to adopt this technology, but rather how quickly and effectively it can be integrated with existing expertise. The farms that thrive in the coming decades will be those that successfully blend the art and science of growing, creating systems that are both highly productive and deeply rooted in agricultural understanding.

The future of agriculture lies not in choosing between tradition and technology, but in the intelligent integration of both approaches to create growing systems that are more productive, sustainable, and profitable than either could achieve alone.